BACKGROUND

Major oil companies are developing new offshore oilfields at an increasing rate. Deepwater offshore oil fields are now an economically viable oil supply option; there is currently a substantial undeveloped deep-water fields’ backlog. Despite the fluctuation in the price of oil, the demand for floating rigs has steadily increased in the past decade. The 2010 Deepwater Horizon incident and the pending new regulatory changes will add higher safety requirements coupled with information sharing to the drilling companies.

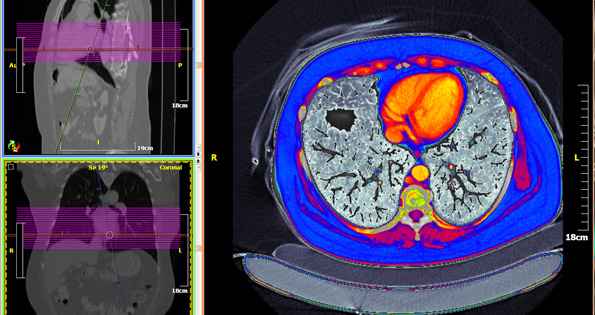

Flexible subsea pipes are used for carrying oil from the deep sea to the offshore platforms and to the floating production, storage, & offloading vessels (FPSOs). When in service, the flexible subsea pipes are expected to operate for the life of the oil field that may be up to 30 years. There is currently (2009) no method of examining, in situ, the underwater risers and flowlines. Subsea radiography has been recognized as the only inspection method that can provide the type of information required to detect the defects, however, there are no mechanized means for deploying such inspection equipment deep-water.

OUR SOLUTION

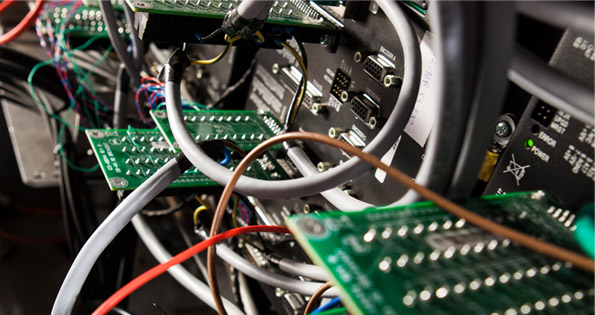

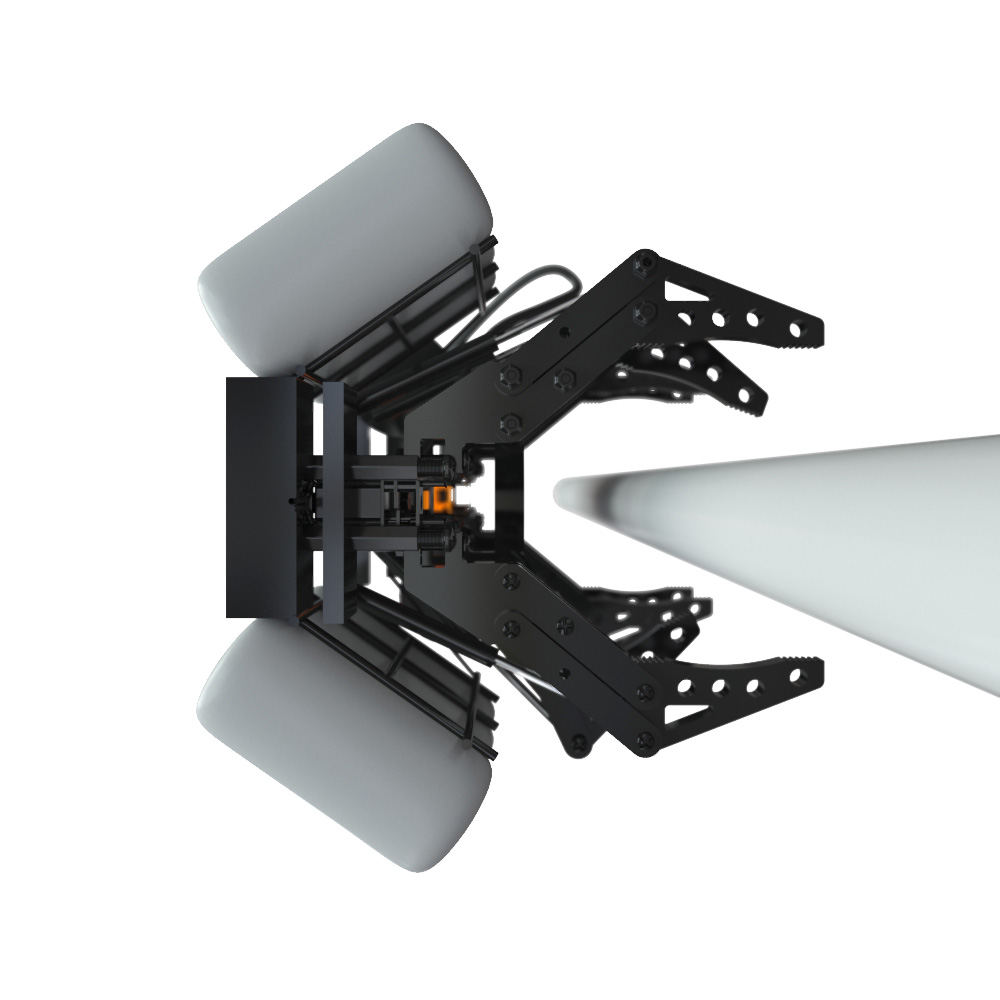

A subsea robotic crawler was designed and engineered to deploy the radiographic equipment. It moves along and around the riser using an inch-worm type motion. The robotic crawler employs four under-actuated end effectors that act in pairs and allow the robot to securely attach itself on the subsea pipes. Designing the appropriate end effectors to be used by the robotic crawler was challenging. Inspired by the designing principles found in prosthetic hands, we ended up developing a shape adaptive gripper allowing the robot to fully adapt to the curved subsea pipes. The developed end-effectors can operate in both open- and closed-loop control schemes. An ROV can also be used to deploy the robot on the subsea pipes.

SKILL-SET

Dynamic Modelling and Simulations / Mechanisms Design and Analysis / Sealing Design / Hydraulics / Materials Selection / 3D CAD Design / System Integration / Testing & System Upgrade.