BACKGROUND

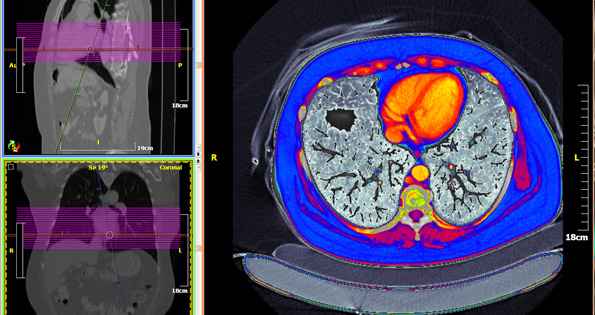

Regular in-service inspections examine the integrity of the welded nozzles present in nuclear power plants. The cracks in boiling water reactor (BWR) nozzles discovered during the 1970s, led to a change in both the design and the materials used in their manufacture. Strict guidelines were established for periodic ultrasonic testing and much of the research work undertaken since the early 1970s involved specialized NDT methods for the in-service inspection of nozzles in boiled water reactors.

Nozzle sections can be susceptible to crack growth due to thermal fatigue and stress corrosion. Early detection of cracks is therefore essential to ensure the continued safe operation of the facilities. To reduce the time and cost of such inspections there is a need to develop a system capable of performing a full inspection of nozzles without the need to change probes.

OUR SOLUTION

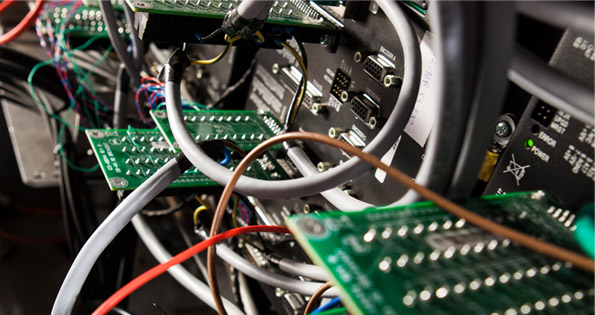

We developed a novel scanner and probe manipulator and combined them with a phased array technique for the inspection of BWR nozzles. Innora’s solution eliminates the need for complex robotic manipulation and reduces the size and cost of robotic deployment systems.

SKILL-SET

Mechanisms analysis, Pneumatics design, Electrical & electronics systems design (motors & amplifiers, sensors, custom driving electronics), Mechanical design for prototyping (sheet metal forming, machining, adhesives joining, materials selection), Systems integration and debugging, Automatic controller algorithm design, Automatic controller low level software development, UI design & development.