BACKGROUND

In 2014 wind power was the world’s fastest growing energy source. With a record-setting 44% year-on-year growth and wind turbine installations crossing the 50 GW mark, wind power is the leading renewable source for electricity generation. Wind covers a little over 10% of EU’s electricity needs, and has the capacity to power over 73 million households. The upward trend is set to continue and by 2019 it is projected that 483,500 wind turbines will be in service.

With an estimated 804,000 blades spinning 24/7, it comes as no surprise that failure rates are an ever-present facet of the industry. Sudden gusts of wind, lightning, and ice contribute to blade wear and ultimately lead to more than 4,000 p.a. blade failure incidents. With the going costs per failure at $1 million, there is a clear incentive to ensure that such incidents are kept to a minimum.

OUR SOLUTION

Wind turbine blade maintenance is a labor-intensive work. To examine and repair the blades, trained operators, known as rope specialists, hang tens of meters above ground many times under adverse conditions. High velocity winds and/or extreme temperatures compose an unpredictable and dangerous working environment, both for man and machine.

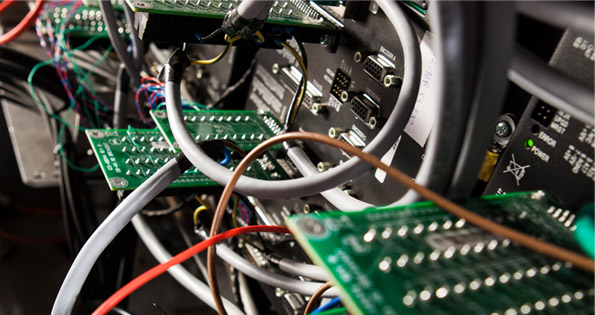

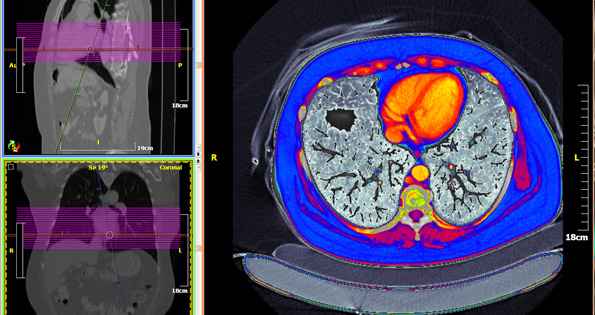

Our solution was to automate access to the blades without deploying rope specialists. The main challenges were the unstructured working environment, aerodynamic forces, strict safety requirements and ease of use. The blade is stalled at a horizontal orientation and with the help of an inbuilt crane a small robot is mounted. The robot moves along the spar and performs ultrasonic testing spot by spot and assesses the blade’s structural integrity. The operator controls the robot’s movement through a joypad. Much like a remote-control car. Our modular design copes with the varying curvature and geometry of the blades. Two powerful vacuum cups provide the required vertical force to withstand winds up to 6 Beaufort. Low weight and small size facilitate easy deployment.

SKILL SET

Functional specifications / concept creation / Mechanisms Design and Analysis / Pneumatics / Electric motors / 3D CAD Design / System Integration / Testing